ASTM A519 Seamless carbon steel pipe for machinery

Still deciding? Get samples first, Contact US !

Tag list

ASTM A519 Seamless carbon steel pipe for machinery

Still deciding? Get samples first, Contact US !

Products Category

Tag list

- Description

-

Product Description

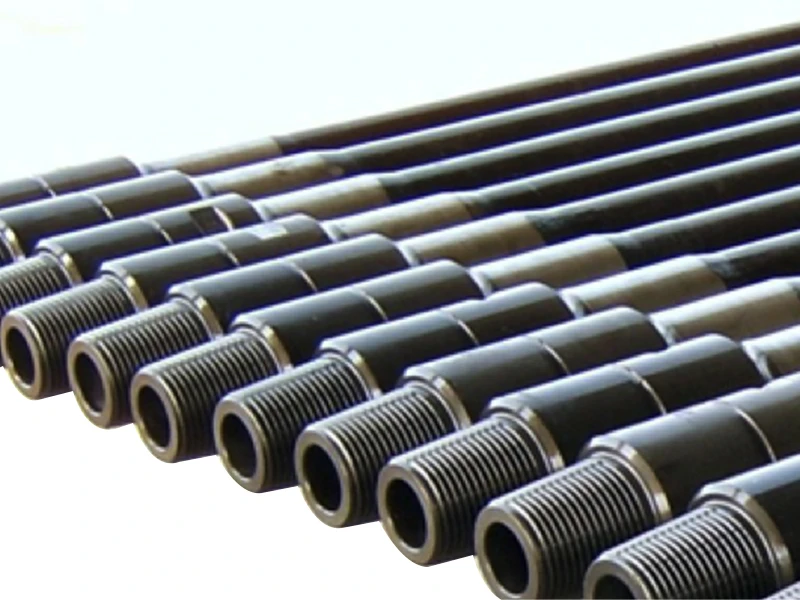

ASTM A519 steel pipe is seamless carbon steel pipe and alloy steel pipe for mechanical use. Steel pipe carbon steel material commonly used grades (chemical composition) 1020, 1025, 1035, 1045, 1050, 1118, 1137 and so on a variety of hot-rolled (extrusion, expansion) or cold-drawn (rolled) process.

Product Size

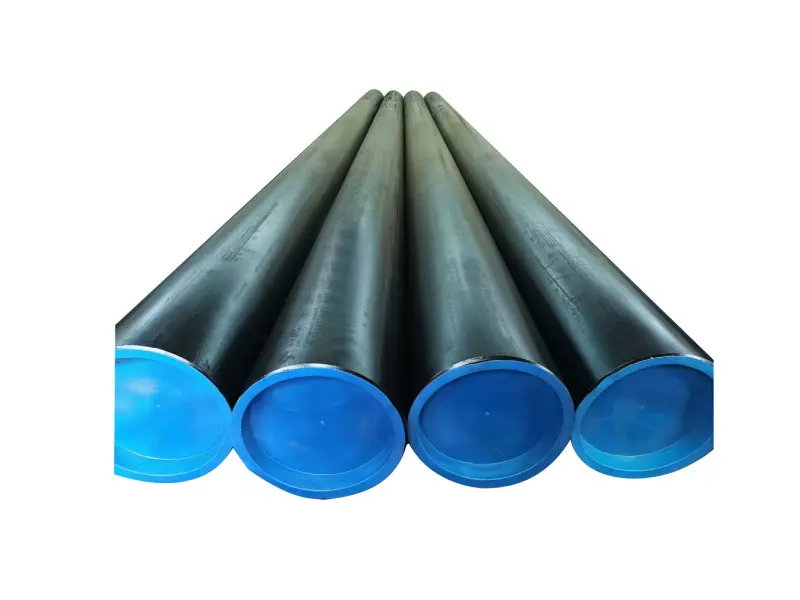

Outer diameter: NPS 1/2~12; 21.3~323.8mm

Wall thickness: SCH 20~160; 2.77~33.32mm

End: Flat end

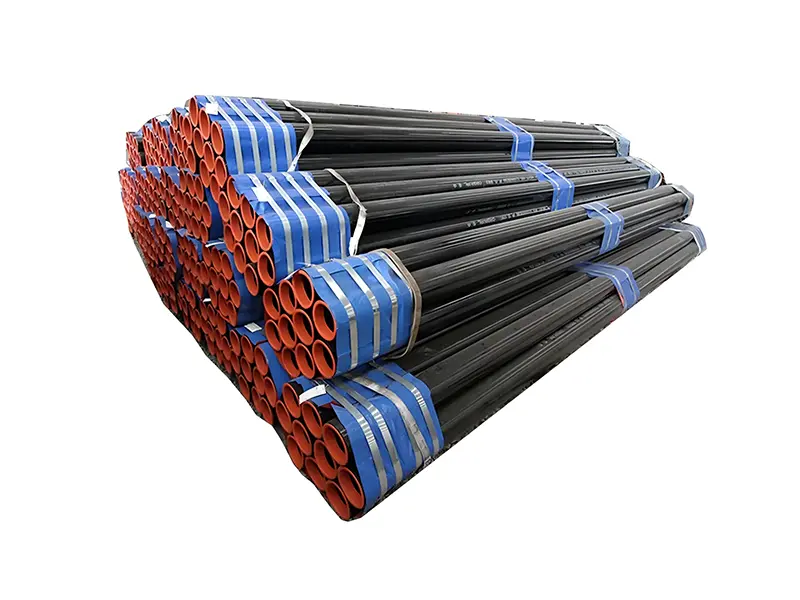

Length: 3 to 12 meters or SRL, DRL, double-footed and fixed-footedProduct Packaging

The outer surface is oiled and strapped with steel tape.

Chemical composition

Grade

C

Mn

P

≤S

≤Si

Ni

Cr

Mo

1008 0.10 max

0.30-0.50

0.040

0.050

1010 0.08-0.13

0.30-0.60

0.040

0.050

1012 0.10-0.15

0.30-0.60

0.040

0.050

1015 0.13-0.18

0.30-0.60

0.040

0.050

1016 0.13-0.18

0.60-0.90

0.040

0.050

1017 0.15-0.20

0.30-0.60

0.040

0.050

1018 0.15-0.20

0.60-0.90

0.040

0.050

1019 0.15-0.20

0.70-1.00

0.040

0.050

1020 0.18-0.23

0.30-0.60

0.040

0.050

1021 0.18-0.23

0.60-0.90

0.040

0.050

1022 0.18-0.23

0.70-1.00

0.040

0.050

1025 0.22-0.28

0.30-0.60

0.040

0.050

1026 0.22-0.28

0.60-0.90

0.040

0.050

1030 0.28-0.34

0.60-0.90

0.040

0.050

1035 0.32-0.38

0.60-0.90

0.040

0.050

1040 0.37-0.44

0.60-0,90

0.040

0.050

1045 0.43-0.50

0.60-0.90

0.040

0.050

1050 0.48-0.55

0.60-0.90

0.040

0.050

1515 0.13-0.18

1.10-1.50

0.040

0.050

1518 0.15-0.21

1.10-1.50

0.040

0.050

1524 0.19-0.25

1.35-1.65

0.040

0.050

1541 0.36-0.44

1.35-1.65

0.040

0.050

1118 0.14-0.20

1.30-1.60

0.040

0.08-0.13

1137 0.32-0.39

1.35-1.65

0.040

0.08-0.13

Product Mechanical Properties

Grade

Delivery Status

Tensile strength

Yield strength

Elongation,%

Rockwell hardness

HRBksi

MPa

ksi

MPa

1020

HR

50

345

32

220

25

55

CW

70

485

60

415

5

75

SR

65

450

50

345

10

72

A

48

330

28

195

30

50

N

55

380

34

235

22

60

1025

HR

55

380

35

240

25

60

CW

75

515

65

450

5

80

SR

70

485

55

380

8

75

A

53

365

30

205

25

57

N

55

380

36

250

22

60

1035

HR

65

450

40

275

20

72

CW

85

585

75

515

5

88

SR

75

515

65

450

8

80

A

60

415

33

230

25

67

N

65

450

40

275

20

72

1045

HR

75

515

45

310

15

80

CW

90

620

80

550

5

90

SR

80

550

70

485

8

85

A

65

450

35

240

20

72

N

75

515

48

330

15

80

1050

HR

80

550

50

345

10

85

SR

82

565

70

485

6

86

A

68

470

38

260

18

74

N

78

540

50

345

12

82

1118

HR

50

345

35

240

25

55

CW

75

515

60

415

5

80

SR

70

485

55

380

8

75

A

50

345

30

205

25

55

N

55

380

35

240

20

60

1137

HR

70

485

40

275

20

75

CW

80

550

65

450

5

85

SR

75

515

60

415

8

80

A

65

450

35

240

22

72

N

70

485

43

295

15

75

Application

Typically used in the construction of mechanical parts.

Production And Processes

We have two pipe product manufacturing bases in Yantai, Shandong Province. One of them, the General Pipe Manufacturing Base, has a history of nearly 70 years and is equipped with five hot-rolling production lines and one cold-drawing production line, with an annual production capacity of up to 500.000 tons. Leveraging our mature production processes and economies of scale, our product range encompasses over 1.000 specifications of pipe products, fully compliant with international standards such as API 5L, ASTM A106. and ASTM A333. While ensuring quality, we also offer a leading price advantage.

Our high-standard pipeline product production base has a stable production capacity of 800.000 tons, primarily producing high-grade steel products such as API 5L X100 PSL2. API 5CT Super 13Cr, and ASTM A335 P91. Our product specifications cover a wide range, with a maximum outer diameter of 20 inches, a wall thickness of up to 70 millimeters, and a single-piece length of up to 36 meters, capable of meeting the demands of steel pipes in various harsh operating conditions.

|

|

|

Inventory And Quality Inspection

We operate under the YANTAIPIPE brand and have established solid partnerships with a number of outstanding manufacturers of steel pipes, pipe fittings, flanges, and valves. We operate three large warehouses and processing plants in Yantai and Cangzhou ensuring a minimum inventory capacity of over 35.000 tons. We not only provide products but also offer comprehensive services such as project packaging, corrosion-resistant coatings, advanced processing, and customized solutions. Through our mature supply chain system and resource integration capabilities, we create added value for our customers from all angles, enabling us to maintain a core competitive advantage in the international market!

Customer Feedback

Qualification

Customer visit

Shipping Packaging

International Cooperation

Our products have been widely used in major energy projects around the world. We provide services to international energy giants, including China National Petroleum Corporation, Sinopec, Shell, Total, as well as national oil companies from Kuwait, Azerbaijan, Abu Dhabi, Qatar, Algeria, and Saudi Arabia. This has allowed us to accumulate extensive experience in serving international projects.

Main Projects

We are deeply involved in major global energy projects, including the Clean Fuel Project of Kuwait National Petroleum Company (KNPC), the North Field East (NFE) LNG Project in Qatar, the multiphase flow processing station project in Hassi Messaoud, Algeria, and the modernization project of SOCAR Haor for the State Oil Company of Azerbaijan (SOCAR). We provide our clients with comprehensive solutions that cover procurement, processing, quality inspection, delivery, and after-sales service.

FAQs

Do you require a minimum order quantity(MOQ)?

We have no minimum order quantity requirements. Even if you only need one steel pipe or one pipe fitting, we can deliver on time and provide comprehensive services. Please note that certain high-grade steel products may require temporary production scheduling, which may result in minimum order quantity requirements. For specific details, please consult our sales team.

Do you offer product samples?

Of course, we provide free samples for products priced below $1,000. You only need to cover the shipping costs. For products priced above $1,000, please contact our sales team to discuss specific fees.

How long is your shipping cycle?

For products that are in stock, we will complete the final processing, quality inspection, packaging, and other steps within two weeks and deliver them as soon as possible according to the shipping schedule. For products that need to be ordered for production, an additional 2-3 weeks of production time will be required depending on the quantity requested.

Do you offer additional quality assurance?

In addition to providing factory warranty certificates, we can also provide test reports from internationally recognized quality testing agencies such as SGS, TUV, and DNV upon customer request. We are also available to assist third-party testing agencies with process inspections and final inspections prior to shipment.

Is it possible to visit your factory?

Of course! Whether it's our own factory, processing plant, or our partners' factories, we welcome you to visit and exchange ideas at any time. If you need our assistance with visa matters, please feel free to contact our sales manager.

Are you a supplier or a manufacturer?

We are both a supplier and a manufacturer. We have three processing plants and warehouses, as well as a seamless steel pipe factory. We also collaborate closely with other outstanding steel pipe and pipe fitting factories in China, enabling us to offer a wide range of product specifications and a complete product system.

Related Products