Categories

Contact Us

E-mail:

info@yantaipipe.cn

WhatsApp:

8615653819370

Tel:

0086-535-6281117

Add:

No. 161 Changjiang Road, FTZ, Yantai, Chine

OCTG

OCTG (Oil Country Tubular Goods) refers to tubular goods used in the oil and gas extraction industry, including oil casing, tubing, and drill pipes. These tubular goods play a crucial role in the drilling and production processes of oil and gas wells, ensuring the efficient and safe extraction of resources. Our OCTG products are made from high-quality steel and comply with international standards (such as API 5CT and API 5DP), offering excellent mechanical properties and corrosion resistance. Depending on specific application requirements, OCTG tubular goods can be manufactured from various materials, including carbon steel, stainless steel, and alloy steel. Drill pipes are used to transport drill bits and drilling fluid to the wellbore, ensuring smooth drilling operations. Casing provides support for the wellbore, preventing collapse, and isolates different geological layers to protect groundwater resources. Tubing is responsible for safely transporting extracted oil and natural gas to the surface.

API Tubing is a critical tubing material specifically designed for the oil and gas industry, primarily used to transport extracted oil and gas from underground wells to the surface. The design of API Tubing not only prioritizes strength and durability but also emphasizes ease of installation. Our products are manufactured using high-quality steel, offering exceptional corrosion resistance and mechanical strength, capable of withstanding high-temperature and high-pressure operational conditions. The tubing is equipped with standardized connectors, enabling quick installation and disassembly, thereby reducing construction time and costs. Each API Tubing is subjected to rigorous quality inspections, meeting the stringent standards set by the American Petroleum Institute (API), ensuring its reliability and safety under high-pressure and extreme environmental conditions.

View More →

API Casing is a critical tubing material specifically designed for the oil and gas industry, primarily used to transport extracted oil and gas from underground wells to the surface. The design of API Casing features excellent corrosion resistance and wear resistance, effectively preventing wellbore collapse and protecting underground resources. Additionally, to meet the demand for quick installation and removal, it is equipped with standardized connectors, significantly improving construction efficiency and reducing operational costs. Each API Casing undergoes rigorous quality testing and meets the stringent standards set by the American Petroleum Institute (API), ensuring its reliability and safety under high-pressure and extreme environmental conditions.

View More →

Casing and Tubing Couplings are essential connection components in the oil and gas industry, primarily used to connect API Casing and API Tubing. Their design is intended to provide robust structural support, prevent wellbore collapse, and ensure safe isolation of fluids within the well, thereby ensuring safety and efficiency during drilling and production operations. Precise thread design and high-quality materials ensure a secure connection, reducing the risk of oil and gas leaks. These couplings are manufactured using high-strength steel, offering excellent corrosion resistance and pressure-bearing capabilities, capable of withstanding the harsh conditions of high-temperature and high-pressure environments. Through the use of advanced manufacturing processes, Casing and Tubing Couplings undergo rigorous quality control and testing, meeting API standards to ensure reliability under various operational conditions and fulfilling customers' diverse needs in oil and gas extraction.

View More →

Casing and Tubing Pup Joints are critical connection components in the oil and gas industry, primarily used to supplement and adjust the length of Casing and Tubing systems. As a short pipe segment, Pup Joints are typically employed during drilling and production operations to enable flexible pipeline configurations, ensuring the integrity and effectiveness of the system. The design of the Pup Joint is engineered to withstand high-pressure and high-temperature environments, constructed from high-strength steel with excellent corrosion resistance. Its precise threaded connections ensure a secure connection with other pipe sections, enhancing construction efficiency and system safety while minimizing the risk of leaks.

View More →

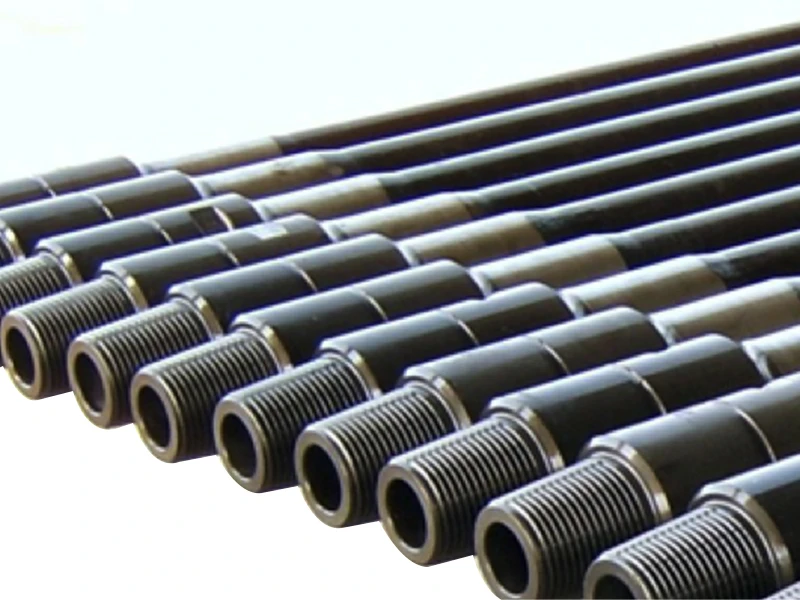

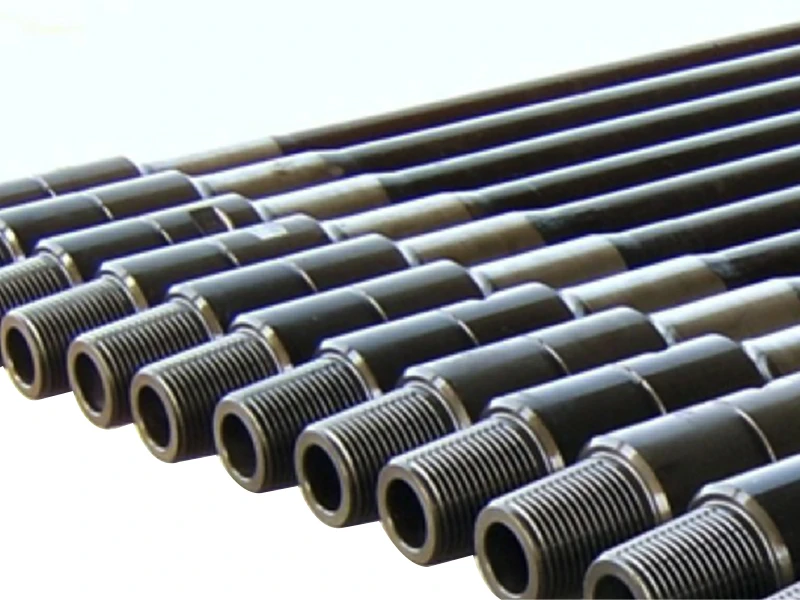

Drill pipe is a core component in the oil and gas industry, serving as a key part of the drilling string. It is responsible for transmitting power from the drilling rig to the drill bit and conveying drilling fluid (mud) to the depths of the well, ensuring efficient and safe drilling operations. Drill pipe is manufactured using high-strength steel, offering exceptional wear resistance and corrosion resistance, enabling reliable performance under extreme geological conditions. Additionally, it offers excellent connectivity, with special threaded joints at both ends that seamlessly connect with other drilling pipes (such as heavy-duty drill pipes and drill collars) to form a complete drilling pipe string. This flexibility allows it to adapt to various drilling operation requirements, delivering outstanding performance whether in onshore or offshore drilling. Each drill pipe undergoes rigorous quality testing and meets API standards.

View More →

Heavy Weight Drill Pipe (HWDP) is a critical component in the oil and gas industry, specifically designed to meet the demands of modern oil and gas drilling operations. HWDP products are manufactured using high-strength steel, offering exceptional wear resistance and corrosion resistance, enabling reliable performance under extreme conditions. They play a crucial role in the drilling string, primarily used to increase drill bit downforce and stability, thereby enhancing drilling efficiency. The unique design of HWDP includes thicker walls and a heavier structure. This additional weight helps enhance the drill bit's drilling capability, particularly in soft soil or unstable formations, reducing the risk of drill bit vibration and twisting, and ensuring smoother drilling operations. Each HWDP is subject to rigorous quality testing and meets API standards.

View More →

Slotted Pipe is a specialized pipe material designed for critical applications in fluid storage and transportation, offering exceptional fluid conveyance capabilities and efficient drainage performance. Manufactured from high-strength materials, Slotted Pipe features superior corrosion resistance and wear resistance, enabling it to effectively withstand diverse soil and water quality conditions. Designed with construction convenience in mind, it features standardized connectors, significantly improving installation efficiency and reducing operational costs. As part of our high-performance pipe range, we offer a variety of specifications and slot configurations to meet the needs of different projects. Each Slotted Pipe undergoes rigorous quality testing and complies with API standards, ensuring stable performance in various operational environments.

View More →