Share to

GB/T 9711-2017 Steel pipe for pipeline transportation system

Still deciding? Get samples first, Contact US !

Tag list

GB/T 9711-2017 Steel pipe for pipeline transportation system

Still deciding? Get samples first, Contact US !

Products Category

Tag list

- Description

-

Product Description

GB/T 9711-2017 steel pipes are steel pipes for pipeline transportation systems in the oil and gas industry, including two product specification levels (PSL1 and PSL2), manufactured by processes such as hot forming or cold drawing.

Product Size

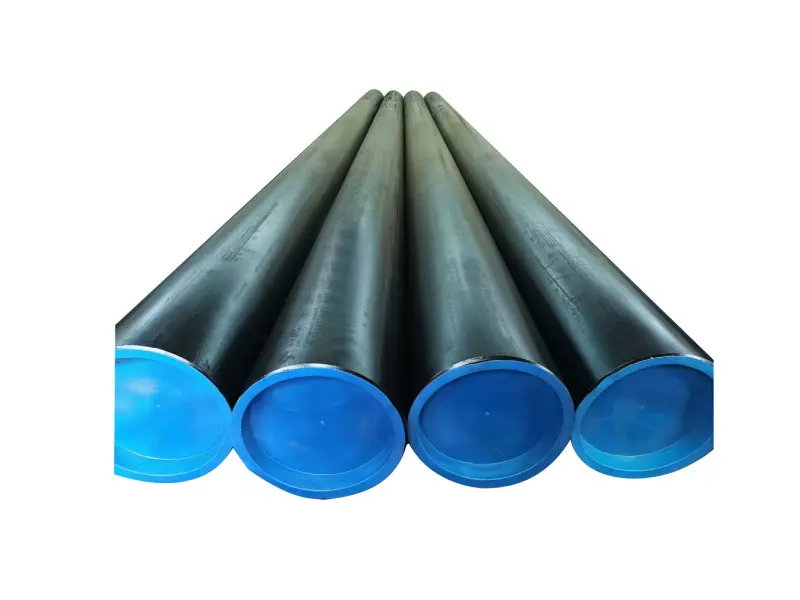

Outer diameter: NPS 1/2~24; 21.3~610mm

Wall thickness: SCH 20~160; 2.77~70.00mm

End: Flat end, beveled or threaded optional

Length: 3 to 12 meters or SRL, DRL, double and fixed feetProduct Packaging

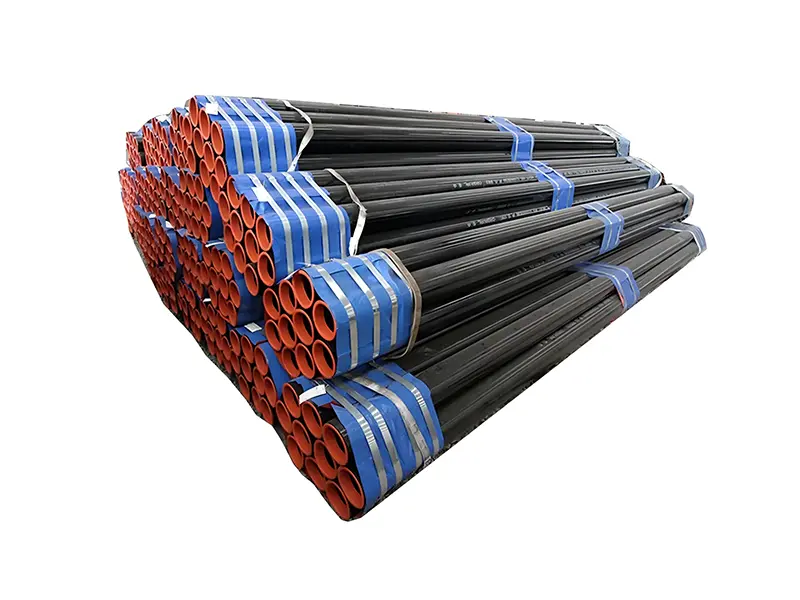

External surfaces varnished clear/black, hot-dipped galvanized or anticorrosive treatment (FBE, 3LP, 3LPP) optional, steel strapping.

Product Mechanical Properties

PSL1 steel pipe mechanical property requirements

Steel grade

Seamless and welded pipe bodies

EW, LW, SAW, and Cow Pipe Welds

Yield strength Rt0.5 ≥, MPa(psi)

Tensile strength Rm ≥, MPa(psi)

Elongation Af ≥, %

Tensile strength Rm ≥, MPa(psi)

L175 (A25)

175(25,400)

310(45,000)

c

310(45,000)

L175P(A25P)

175(25,400)

310(45,000)

c

310(45,000)

L210(A)

210(30,500)

335(48,600)

c

335(48,600)

L245(B)

245(35,500)

415(60,200)

c

415(60,200)

L290(X42)

290(42,100)

415(60,200)

c

415(60,200)

L320(X46)

320(46,400)

435(63,100)

c

435(63,100)

L360(X52)

360(52,200)

460(66,700)

c

460(66,700)

L390(X56)

390(56,600)

490(71,100)

c

490(71,100)

L415(X60)

415(60,200)

520(75,400)

c

520(75,400)

L450(X65)

450(65,300)

535(77,600)

c

535(77,600)

L485(X70)

485(70,300)

570(82,700)

c

570(82,700)

PSL2 steel pipe mechanical property requirements

Steel grade Seamless and welded pipe bodies

HFW, SAW and COW Pipe Welds

Yield strength Rt0.5 ≥, MPa(psi)

Tensile strength Rm ≥, MPa(psi)

Ductility ratio Rto.₅/Rm

Elongation Af ≥, %

Tensile strength Rm ≥, MPa(psi)

min

max

min

max

max

max

min

L245R(BR)

L245N(BN)

L245Q(BQ)

L245M(BM)245

(35,500)450

(65,300)415 (60,200) 655 (95,000) 0.93

See product standards for details 415

(60,200)L290R(X42R)

L290N(X42N)

L290Q(X42Q)

L290M(X42M)290

(42.100)495

(71,800)415 (60,200) 655 (95,000) 0.93

415

(60,200)L320N(X46N)L320Q(X46Q)

L320M(X46M)320

(46,400)525

(76,100)435 (63.100) 655 (95,000) 0.93

435

(63.100L360N(X52N)

L360Q(X52Q)

L360M(X52M)360

(52,200)530

(76,900)460 (66,700) 760

(110,2000.93

460

(66,700)L390N(X56N)

L390Q(X56Q)

L390M(X56M)390

(56,600)545

(79,000)490 (71,100) 760 (110,200) 0.93

490

(71.100L415N(X60N)

L415Q(X60Q)

L415M(X60M)415

(60,200)565

(81,900)520 (75,400) 760 (110,200) 0.93

520

(75,400)L450Q(X65Q)

L450M(X65M)450

(65,300)600

(87,000)535 (77,600) 760 (110,200) 0.93

535

(77,600)L485Q(X70Q)

L485M(X70M)485

(70,300)635

(92,100)570 (82,700) 760 (110,200) 0.93

570

(82,700)L555Q(X80Q)

L555M(X80M)555

(80,500)705

(102,300)625 (90,600) 825 (119,700) 0.93

625(90,600) L625M(X90M)

625

(90,600)775

(112,400)695 (100,800) 915 (132,700) 0.95

695

(100,800)L625Q(X90Q)

625

(90,600)775

(112,400)695 (100,800) 915 (132,700) 0.979

L690M(X100M)

690

(100,100)840

(121,800)760 (110,200) 990 (143,600) 0.97

760

(110,200)L690Q(X100Q)

690

(100,100)840

(121,800)760 (110,200) 990 (143,600) 0.97

L830M(X120M)

830

(120,400)1050

(152,300)915 (132,700) 1145 (166,100) 0.99

915

(132,700)Application

Typically used in pipeline transportation systems in the oil and gas industry.

Related Products