Share to

GB/T 5310 Seamless Steel Tubes for High Pressure Boilers

Still deciding? Get samples first, Contact US !

GB/T 5310 Seamless Steel Tubes for High Pressure Boilers

Still deciding? Get samples first, Contact US !

Products Category

- Description

-

Product Description

GB/T 5310 steel pipe is seamless steel pipe for high pressure boiler, which can be bent, crimped and similar processed to shape, also suitable for welding operations. Steel pipe alloy steel material commonly used grade (chemical composition) 15MoG, 12CrMoG, 15CrMoG, 12Cr1MoVG and so on many kinds of, using hot rolling (extrusion, expansion) or cold drawing (rolling) process.

Product Size

Outer diameter: 21.0~610.0mm

Wall thickness: 2.00~70.00mm

End: Flat end, beveling optional

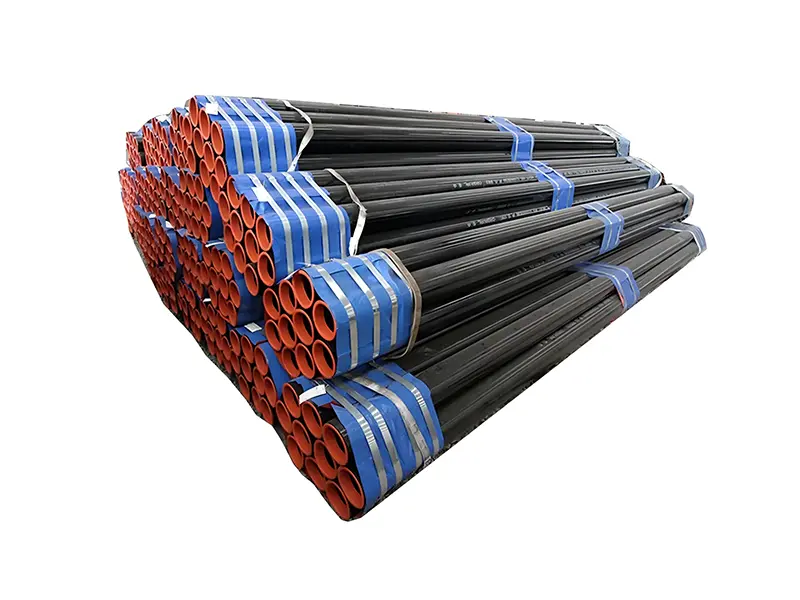

Length: 3 to 12 meters or SRL, DRL, double and fixed feetProduct Packaging

Clear/black paint on exterior surfaces, steel strapping.

Chemical composition

Grades/Elements

C

Mn

Si

P

S

Cr

V

Mo

Ni

Cu

%

≤,%

%

≤,%

15MoG

0.12~0.20

0.40~0.80

0.17~0.37

0.025

0.015

≤0.30

≤0.08

0.25~0.35

0.30

0.20

12CrMoG

0.08~0.15

0.40~0.70

0.17~0.37

0.025

0.015

0.40~0.70

≤0.08

0.40~0.55

0.30

0.20

15CrMoG

0.12~0.18

0.40~0.70

0.17~0.37

0.025

0.015

0.80~1.10

≤0.08

0.40~0.55

0.30

0.20

12Cr1MoVG

0.08~0.15

0.40~0.70

0.17~0.37

0.025

0.010

0.90~1.20

0.15~0.30

0.25~0.35

0.30

0.20

Product Mechanical Properties

Grades/Items Tensile Strength(MPa)

Yield strength ≥, MPa

Elongation after break ≥, %

Shock absorption capacity

Hardness

vertically

orthogonal

vertically

orthogonal

Brinell HBW

Vickers HV

Luoshi

15MoG

450~600

270

22

20

40

27

125~180

130~190

12CrMoG

410~560

205

21

19

40

27

125~170

130~180

15CrMoG

440~640

295

21

19

40

27

125~195

130~205

12Cr1MoVG

470~640

255

21

19

40

27

135~195

140~205

Application

Typically used in the construction of petroleum and petrochemical refineries, power plants, boilers and ships that transport fluids and gases with high temperatures and pressures.

Related Products