Share to

API 5L PSL1&PSL2

Still deciding? Get samples first, Contact US !

Tag list

API 5L PSL1&PSL2

Still deciding? Get samples first, Contact US !

Products Category

Tag list

- Description

-

Product Description

API 5L steel pipe is seamless and welded pipe for pipeline transportation systems in the oil and gas industry. It consists of two product specification levels (PSL1 and PSL2), and the welded pipe is manufactured using the CW, LFW, HFW, LW, SAWL, SAWH, COWL, and COWH processes.

Product Size

OD: NPS 3''-80'' ; 88.9~2032mm

Wall thickness: 4~60.00mm

End: Flat end, beveled or threaded for selection

Length: 3 to 12 meters or SRL, DRL, double and fixed feet

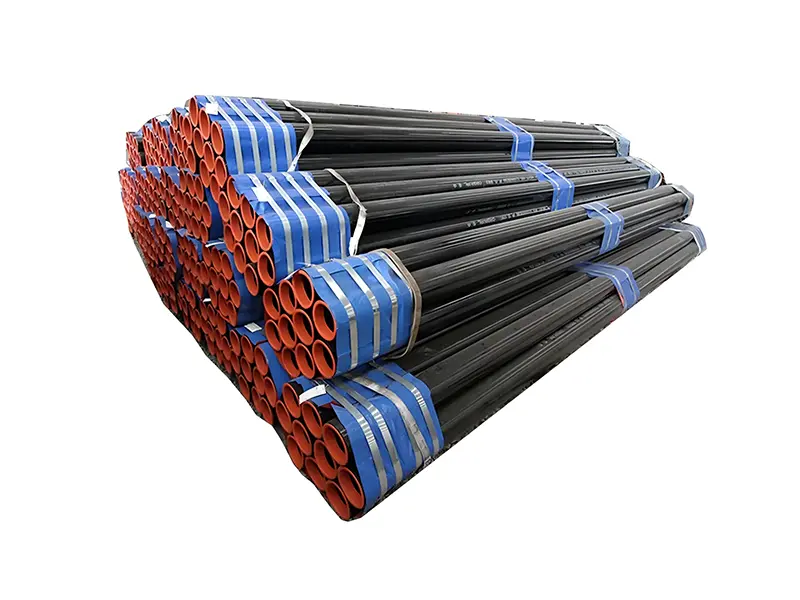

Packaging

Clear/black painted, hot-dipped galvanized or anti-corrosion treatment (FBE, 3LP, 3LPP) on external surfaces, steel strapping.

Chemical composition

1.Chemical composition of PSL1 tubes with wall thickness ≤ 25.0 mm

Steel grade C Mn P S V Nb Ti Other a,g ≤b,% ≥,% ≤,% ≤,% L175 (A25) 0.21 0.60 0.030 0.030 L175P(A25P) 0.21 0.60 0.045 0.080 0.030 L210(A) 0.22 0.90 0.030 0.030 L245(B) 0.26 1.20 0.030 0.030 c,d c,d d L290(X42) 0.26 1.30 0.030 0.030 d d d L320(X46) 0.26 1.40 0.030 0.030 d d d L360(X52) 0.26 1.40 0.030 0.030 d d d L390(X56) 0.26 1.40 0.030 0.030 d d d L415(X60) 0.26e 1.40e 0.030 0.030 f f f L450(X65) 0.26e 1.45e 0.030 0.030 f f f L485(X70) 0.26e 1.65e 0.030 0.030 f f f a. Cu ≤ 0.50%; Ni ≤ 0.50%; Cr ≤ 0.50% and Mo ≤ 0.15%.

b. For every 0.01% decrease in carbon content from the specified maximum carbon content, the permissible manganese content shall be increased by 0.05% from the specified maximum manganese content, which shall be 1.65% for steel grades ≥ L245(B),but ≤ L360(X52), and 1.75% for steel grades > L360(X52),but < L485(X70); For steel grades > L360 (X52), but < L485 (X70), a maximum of 1.75% manganese.

c. Nb+V ≤ 0.06 % unless otherwise agreed.

d. Nb+V+Ti ≤ 0.15 %.

e. Unless otherwise agreed.

f. Nb+V+Ti ≤ 0.15 % unless otherwise agreed.

g. Intentional addition of boron is not permitted and the residual boron content is to be ≤ 0.001 %.

2.Wall thickness ≤ 25.0mm PSL2 tube chemical composition

Steel grade Chemical composition ≥, % Carbon equivalent a ≥, % Cb Si Mnb P S V Nb Ti Other CEIIW CEPCM L245R(BR) 0.24 0.40 1.20 0.025 0.015 c c 0.04 e,i 0.43 0.25 L290R(X42R) 0.24 0.40 1.20 0.025 0.015 0.06 0.05 0.04 e,i 0.43 0.25 L245N(BN) 0.24 0.40 1.20 0.025 0.015 0.04 e,i 0.43 0.25 L290N(X42N) 0.24 0.40 1.20 0.025 0.015 0.06 0.05 0.04 e,i 0.43 0.25 L320N(X46N) 0.24 0.40 1.40 0.025 0.015 0.07 0.05 0.04 d,e,i 0.43 0.25 L360N(X52N) 0.24 0.45 1.40 0.025 0.015 0.10 0.05 0.04 d,e,i 0.43 0.25 L390N(X56N) 0.24 0.45 1.40 0.025 0.015 0.10f 0.05 0.04 d,e,i 0.43 0.25 L415N(X60N) 0.24 0.45f 1.40f 0.025 0.015 0.10f 0.05f 0.04 g.h,i As agreed L245Q(BQ) 0.18 0.45 1.40 0.025 0.015 0.05 0.05 0.04 e, 0.43 0.25 L290Q(X42Q) 0.18 0.45 1.40 0.025 0.015 0.05 0.05 0.04 e, 0.43 0.25 L320Q(X46Q) 0.18 0.45 1.40 0.025 0.015 0.05 0.05 0.04 e,l 0.43 0.25 L360Q(X52Q) 0.18 0.45 1.50 0.025 0.015 0.05 0.05 0.04 e,I 0.43 0.25 L390Q(X56Q) 0.18 0.45 1.50 0.025 0.015 0.07 0.05 0.04 d,e,I 0.43 0.25 L415Q(X60Q) 0.18f 0.45f 1.70f 0.025 0.015 g g g h,I 0.43 0.25 L450Q(X65Q) 0.18f 0.45f 1.70f 0.025 0.015 g g g h, 0.43 0.25 L485Q(X70Q) 0.18f 0.45f 1.80f 0.025 0.015 g g g h,I 0.43 0.25 L555Q(X80Q) 0.18f 0.45 1.90 0.025 0.015 g g g ij As agreed L625Q(X90Q) 0.16f 0.45 1.90 0.020 0.010 g g g j,k As agreed L690Q(X100Q) 0.16 0.45f 1.90 0.020 0.010 g g g j,k As agreed L245M(BM) 0.22 0.45 1.20 0.025 0.015 0.05 0.05 0.04 e,i 0.43 0.25 L290M(X42M) 0.22 0.45 1.30 0.025 0.015 0.05 0.05 0.04 e,j 0.43 0.25 L320M(X46M) 0.22 0.45 1.30 0.025 0.015 0.05 0.05 0.04 e,l 0.43 0.25 L360M(X52M) 0.22 0.45 1.40 0.025 0.015 d d d e,l 0.43 0.25 L390M(X56M) 0.22 0.45 1.40 0.025 0.015 d d d e,i 0.43 0.25 L415M(X60M) 0.12 0.45f 1.60f 0.025 0.015 g g g h,i 0.43 0.25 L450M(X65M) 0.12f 0.45f 1.60f 0.025 0.015 g g g h,i 0.43 0.25 L485M(X70M) 0.12 0.45f 1.70f 0.025 0.015 g g g h,i 0.43 0.25 L555M(X80M) 0.12 0.45f 1.85f 0.025 0.015 g g g i, 0.43f 0.25 L625M(X90M) 0.10 0.55f 2.10f 0.020 0.010 g g g i,l 0.25 L690M(X100M) 0.10 0.55 2.10f 0.020 0.010 g g g I,j 0.25 L830M(X120M) 0.10 0.55f 2.10f 0.020 0.010 g g g I,j 0.25 a. Based on the results of product analysis, for welded pipes with a wall thickness >20.0 mm, the limit value of carbon equivalent shall be determined by agreement. For carbon content C > 0.12 % use CEiiw, for carbon content C ≤ 0.12 % use CEpcm.

b. For every 0.01 % decrease in carbon content over the specified maximum carbon content, the manganese content is allowed to increase by 0.05 % over the specified maximum manganese content. For steel grades ≥ L245 (B), but ≤ L360 (X52), the maximum manganese content shall be 1.65 %; for steel grades > L360 (X52), but < L485 (X70), the maximum manganese content shall be 1.75%; for steel grades For grades >L360 (X52), but

L555 (X80), the maximum manganese content is 2.20%. c. Nb+V ≤ 0.06 %, unless otherwise agreed.

d. Nb + V + Ti ≤ 0.15%

e. Unless otherwise agreed, Cu ≤ 0.50 %; Ni ≤ 0.30 %; Cr ≤ 0.30 % and Mo ≤ 0.15 %. f. Unless otherwise agreed.

f. Unless otherwise agreed.

g. Unless otherwise agreed, Nb+V+Ti≤0.15%. h. Unless otherwise agreed.

h. Unless otherwise agreed, Cu ≤ 0.50%; Ni ≤ 0.50%; Cr ≤ 0.50% and Mo ≤ 0.50%. i Unless otherwise agreed.

i. Unless otherwise agreed, Cu ≤ 0.50%; Ni ≤ 1.00%; Cr ≤ 0.50% and Mo ≤ 0.50%. ii.

j. B ≤ 0.004%.

k. Cu ≤ 0.50%; Ni ≤ 1.00%; Cr ≤ 0.55% and Mo ≤ 0.80%.

l For all PSL2 grades other than those to which footnote j has been applied, the following applies: unless otherwise agreed, intentional addition of boron is not permitted and the residual boron content is to be ≤ 0.001%.

Product Mechanical Properties

1.Mechanical properties of PSL1 steel pipe requirements

Steel grade Welded Pipe Body EW, LW, SAW, and Cow Pipe Welds Yield strength Rt0.5

≥, MPa(psi)Tensile strength Rm

≥, MPa(psi)Elongation Af

≥, %Tensile strength Rm

≥, MPa(psi)L175 (A25) 175(25,400) 310(45,000) c 310(45,000) L175P(A25P) 175(25,400) 310(45,000) c 310(45,000) L210(A) 210(30,500) 335(48,600) c 335(48,600) L245(B) 245(35,500) 415(60,200) c 415(60,200) L290(X42) 290(42,100) 415(60,200) c 415(60,200) L320(X46) 320(46,400) 435(63,100) c 435(63,100) L360(X52) 360(52,200) 460(66,700) c 460(66,700) L390(X56) 390(56,600) 490(71,100) c 490(71,100) L415(X60) 415(60,200) 520(75,400) c 520(75,400) L450(X65) 450(65,300) 535(77,600) c 535(77,600) L485(X70) 485(70,300) 570(82,700) c 570(82,700) 2. PSL2 steel pipe mechanical property requirements

Steel grade Welded Pipe Body HFW, SAW and COW Pipe Welds Yield strength Rt0.5

≥, MPa(psi)Tensile strength Rm

≥, MPa(psi)Ductility ratio Rto.₅/Rm Elongation Af

≥, %Tensile strength Rm ≥, MPa(psi) min. max. min. max. max. max. min. L245R(BR)

L245N(BN)

L245Q(BQ)

L245M(BM)245

(35,500)450

(65,300)415

(60,200)655

(95,000)0.93 See product standards for details 415

(60,200)L290R(X42R)

L290N(X42N)

L290Q(X42Q)

L290M(X42M)290

(42.100)495

(71,800)415

(60,200)655

(95,000)0.93 415

(60,200)L320N(X46N)L320Q(X46Q)

L320M(X46M)320

(46,400)525

(76,100)435

(63.100)655

(95,000)0.93 435

(63.100L360N(X52N)

L360Q(X52Q)

L360M(X52M)360

(52,200)530

(76,900)460

(66,700)760

(110,200)0.93 460

(66,700)L390N(X56N)

L390Q(X56Q)

L390M(X56M)390

(56,600)545

(79,000)490

(71,100)760

(110,200)0.93 490

(71.100L415N(X60N)

L415Q(X60Q)

L415M(X60M)415

(60,200)565

(81,900)520

(75,400)760

(110,200)0.93 520

(75,400)L450Q(X65Q)

L450M(X65M)450

(65,300)600

(87,000)535

(77,600)760

(110,200)0.93 535

(77,600)L485Q(X70Q)

L485M(X70M)485

(70,300)635

(92,100)570

(82,700)760

(110,200)0.93 570

(82,700)L555Q(X80Q)

L555M(X80M)555

(80,500)705

(102,300)625

(90,600)825

(119,700)0.93 625

(90,600)L625M(X90M) 625

(90,600)775

(112,400)695

(100,800)915

(132,700)0.95 695

(100,800)L625Q(X90Q) 625

(90,600)775

(112,400)695

(100,800)915

(132,700)0.979 L690M(X100M) 690

(100,100)840

(121,800)760 (110,200) 990 (143,600) 0.97 760

(110,200)L690Q(X100Q) 690

(100,100)840

(121,800)760 (110,200) 990 (143,600) 0.97 L830M(X120M) 830

(120,400)1050

(152,300)915 (132,700) 1145 (166,100) 0.99 915

(132,700)Application range

Usually used in oil and gas industry pipeline transportation system.

Related Products