Share to

GB/T 30063

Still deciding? Get samples first, Contact US !

Tag list

GB/T 30063

Still deciding? Get samples first, Contact US !

Products Category

Tag list

- Description

-

Product Description

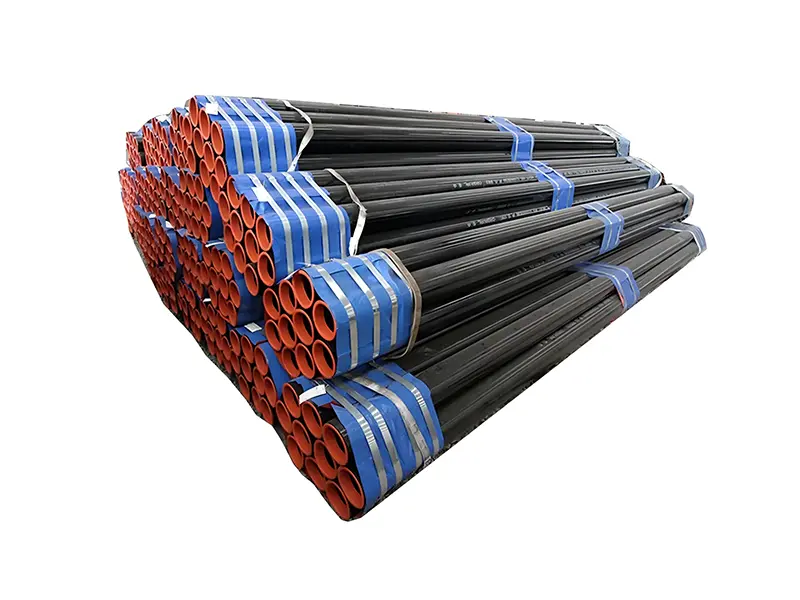

The implementation of GB/T 30063 standard steel pipe for the structure of straight seam submerged arc welded steel pipe, can be bent, rolled edges and similar processing and forming, also suitable for welding operations. Carbon steel pipe material grades (chemical composition) are 10, 20, 35, 45, 20Mn, 25Mn, etc. It is manufactured by hot forming or cold drawing process.

Product Size

Outer diameter: 406~1930mm

Wall thickness: 6.00~70.00mm

End: Flat end

Length: 3~12 meters or SRL, DRL, double and fixed feet.Packaging

Outer surface coated with oil or clear/black paint, also hot-dip galvanized, bundled with steel straps.

Chemical composition

C

Si

Mn

P

S

Cr

Ni

V

Nb

Ti

Al

≤,%

≤,%

≥,%

Q235B

0.20

0.35

1.40

0.045

0.045

0.30

0.30

Q235C

0.17

0.35

1.40

0.040

0.040

0.30

0.30

Q345B

0.20

0.55

1.00~1.60

0.040

0.040

0.30

0.30

0.02~0.15

0.015~0.060

0.02~0.20

Q345C

0.20

0.55

1.00~1.60

0.035

0.035

0.30

0.30

0.02~0.15

0.015~0.060

0.02~0.20

0.015

Q390B

0.20

0.55

1.00~1.60

0.040

0.040

0.30

0.70

0.02~0.20

0.015~0.060

0.02~0.20

Q390C

0.20

0.55

1.00~1.60

0.035

0.035

0.30

0.70

0.02~0.20

0.015~0.060

0.02~0.20

0.015

Q420B

0.20

0.55

1.00~1.70

0.040

0.040

0.40

0.70

0.02~0.20

0.015~0.060

0.02~0.20

Q420C

0.20

0.55

1.00~1.70

0.035

0.035

0.40

0.70

0.02~0.20

0.015~0.060

0.02~0.20

0.015

Q460C

0.20

0.55

1.00~1.70

0.035

0.035

0.70

0.70

0.02~0.20

0.015~0.060

0.02~0.20

0.015

Q460D

0.20

0.55

1.00~1.70

0.030

0.030

0.70

0.70

0.02~0.20

0.015~0.060

0.02~0.20

0.015

Product Mechanical Properties

Tensile strength MPa

Yield strength ≥, MPa

Elongation after break ≥, %

Welded joint tensile strength ≥, MPa

Impact Tests

thickness≤16mm

16mm<thickness≥40mm

40mm<thickness≥60mm

Temp.

℃Average absorbed work ≥, J

Q235B

370~500

235

225

215

22

370

+20

27

Q235C

370~500

235

225

215

22

370

0

27

Q345B

470~630

345

335

325

18

470

+20

34

Q345C

470~630

345

335

325

18

470

0

34

Q390B

490~650

390

370

350

18

490

+20

34

Q390C

490~650

390

370

350

18

490

0

34

Q420B

520~680

420

400

380

17

520

+20

34

Q420C

520~680

420

400

380

17

520

0

34

Q460C

550~720

460

440

420

15

550

0

34

Q460D

550~720

460

440

420

15

550

-20

34

Application range

Typically used in the construction of buildings, bridges, piles, stanchions and other general structures (except mechanical structures).

Related Products